- Product

Product Details

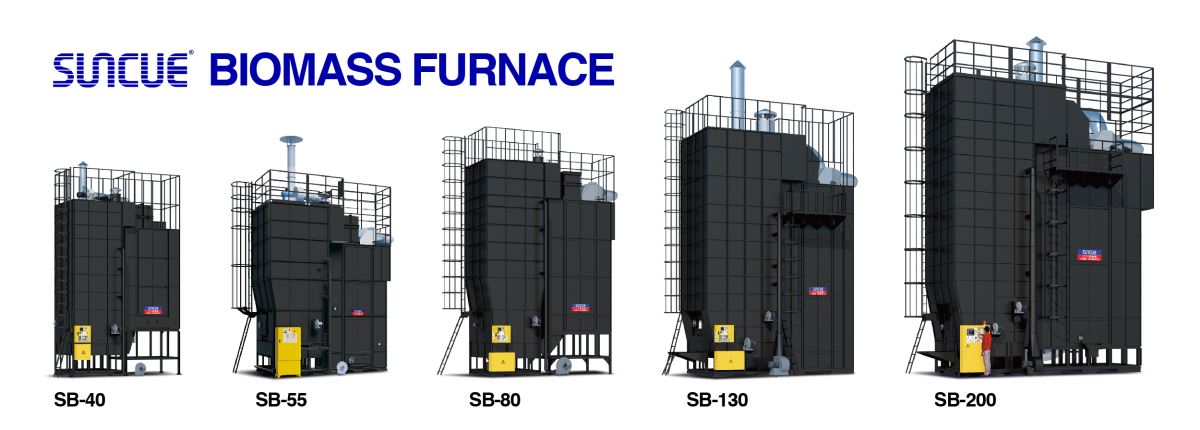

Husk Furnace〈SB Series〉

SB-55

About this product

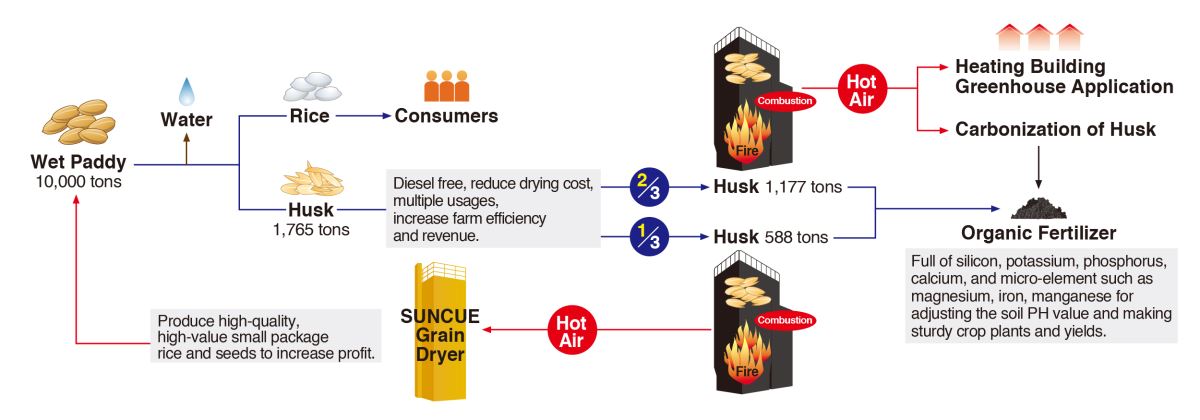

Energy Saving, Environmentally Friendly, Carbon Reduction

Exclusively Patented in Taiwan, USA, Japan, Korea, China, Southeast Asia…etc.

Easy operation-One operator can manage thousands of tons of grains per day

Recycling in the eco-system & Endless care for the Earth

The only choice for producing best quality small-package rice with the lowest cost

Product Introduction

Biomass Furnace SB-55 • Using rice husk as biomass fuel greatly reduces drying cost.

Fuel is free if the rice husk is from your own rice mill.

• The clean and genuine indirect hot air with automatic temperature control allows a low temp.,

even and fast drying. Reduces broken rice, improves milling yield and rice appearance.

• Appraisals from worldwide users: the dried paddy is naturally fragrant and the rice tastes more tender.

It is the real organic rice.

• Foolproof design. Durable for heavy-duty and requires low maintenance.

Allowing consistent high-quality rice from the 1st, 100th to 1000th batch.

The only choice for producing best quality small-package rice with the lowest cost

Low Drying Cost Significantly reduces drying cost! You're no longer at the mercy of rising oil prices. Easy Management Automatic computerized control, fool-proof design, easy operation. Best Rice Quality Drying at constant temperature produces the most high-quality rice, paddy seeds and wheat seeds.

High Selling Price

Indirect and clean hot-air at low temperature can produce the sanitary, reliable of small package rice. Selling price will be high. Energy Saving, Environmentally Friendly, Carbon Reduction

Energy Saving

For example, assuming a rice mill's annual production is 10,000 tons, and 200,000 liters of diesel are needed for drying, which will cost up to USD$ 167,643 of fuel in 1 year.

Buying husk for drying, the drying cost will only be the one-fifth of the diesel cost. If self-milled free husk is used, the fuel cost will be 0.

The diesel price shown here is CPC's diesel price as of March 17th, 2025, which is about USD$ 0.84 per liter.

Environmentally Friendly & Carbon Reduction

Annually reduce 540 tons of CO2 emission, which equal to the volume that a 36 hectares of forest can absorb.

Exclusively Patented in Taiwan, USA, Japan, Korea, China, Southeast Asia…etc. SUNCUE Rice Husk Furnace Drying Complex

| 1 Husk Tank Feeder | 2 Husk Tank |

| 3 Husk Feeder | 4 Rice Husk Furnace SB-200 |

| 5 Main Control Box | 6 Auxiliary Air Blower |

| 7 Auto Ash Discharger | 8 Cyclone |

| 9 Hot Air Duct | 10 Dumping Pit |

| 11 Bucket Elevator | 12 Wet Grain Silo |

| 13 Precleaner | 14 Loading Chain Conveyor |

| 15 32-ton husk type grain dryer | 16 Micro Air Adjuster |

| 17 Hot Air Damper | 18 Unloading Chain Conveyor |

| 19 Dry Grain Silo | |

Recycling in the eco-system & Endless care for the Earth

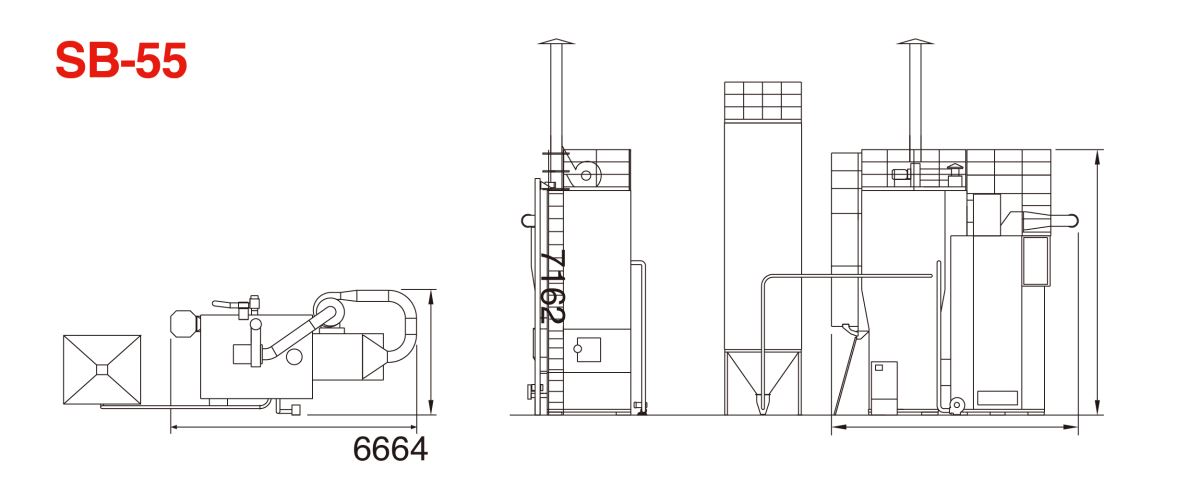

Specifications

Specifications| Item | SB-55 |

Max. Thermal Energy

Approx. Kcal/hr | 550,000 |

quivalent to Diesel Consumption

Approx. liter/day

Diesel thermal energy = approx. 8,400 Kcal/liter | 1,571 |

Husk Consumption

Approx. kg/day under max. combustion

Husk thermal energy = approx. 3,300 Kcal/kg | 4,456 |

Ash Discharge

Approx. kg/day under max. combustion | 576 |

Reduction of CO2 Emission

Approx. ton/day | 4.2 |

| Power Consumption kW | 8.38 |

| Net Weight Approx. in ton | 14 |

| Dimension L×W×H mm | 6,664×3,388×7,162 |

Furnace Connecting Capacity

dryer tons | Commercial Paddy | 28~60 |

| Paddy Seed, Wheat Seed | 33~90 |

| Safety Devices | Abnormal Combustion Sensor, Flame Sensor,

Automatic Abnormal Safe Guard,Thermal Relay,

Rotation Sensor, Control Fuse |

Dimension Unit mm

Product Remark

◆ Max. thermal energy, husk consumption and ash discharge production listed are for reference only. Actual data will differ upon variety, moisture content and impurity.

◆ The specification and graph are for reference only. Actual specification of SUNCUE product shall be based on the Sales Confirmation which customers sign and delivered products.

◆ The maximum heat output of each rice husk furnace is approximately 2.7 kg of CO2 emission per liter of diesel with a running time of 24 hours per day as calculation basis. Actual values may vary due to the users' various using factors.

Related Products