- Product

Product Details

PHS Series

PHS-130

About this product

◆ Can dry rapidly, evenly at low temperature.

◆ The rate of broken rice would be low and the appearance rice will be beautiful, achieving high milling yield.

◆ Can use rice husk as biomass fuel to minimize drying costs.

Product Introduction

PHS-130 Series • The low-temp., even and speedy drying minimizes broken rice, raises milling rate and produces beautiful rice.

• The entire dryer is designed to be strong and sturdy, making it suitable for heavy-duty.

• With foolproof design, users can produce high-quality rice from the 1st, 100th to 1000th batch.

Small-package rice consistent in quality will be available to customers.

• Automatic moisture control prevents over-drying and weight loss.

• By using self-milled free rice husk, users no longer need to spend on diesel, natural gas or electricty as dryers' heat sources.

Multiple models with various fuel options availabl | Heat Source | PHS-130 Series |

| Diesel | ● |

| Gas | ● |

| Biomass | ● |

| Diesel & Husk Dual | ● |

| Gas & Husk Dual | ● |

| Steam | - |

Application Specifications Unit mm| Item | PHS-130 |

| Heat Source | Kerosene or Premium Diesel* |

| Combustion Approx. liter/hr | 8.8~17.5 |

| Type | Gun type |

Capacity

Approx. kg | Paddy 1 liter=560g | 3,600~13,000 |

| Wheat 1 liter=680g | 4,370~15,780 |

Corn, Animal Feed

1 liter=690g | 4,440~16,000 |

Dimension

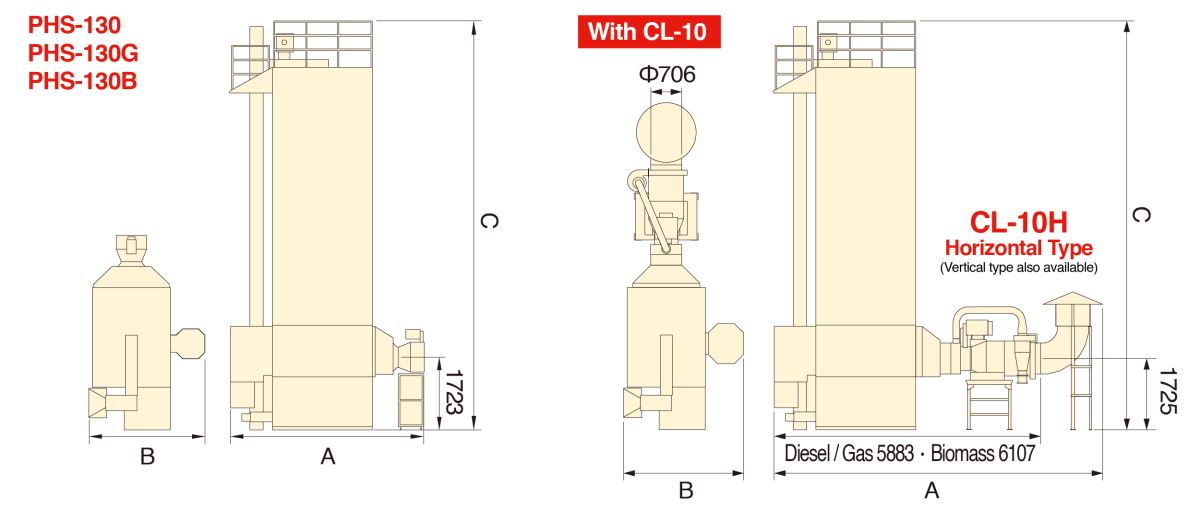

L(A)×W(B)×H(C) mm | Without CL-10 | 4,308×2,755×9,698 |

| With CL-10 | Horizontal Type | 7,393×2,755×9,698 |

| Vertical Type | Please contact the sales department |

Net Weight

Approx. kg | Without CL-10 | 2,840 |

| With CL-10 | Horizontal Type | 3,344 |

| Vertical Type | Please contact the sales department |

Power Consumption

kW | Without CL-10 | 6.53 |

| With CL-10 | 10.33 |

Function

Paddy | Loading Approx. mins | 40 |

| Discharging Approx. mins | 35 |

| Drying Rate %/hr | 0.5~1.5 |

| Electricity | 3P, 220V/380V/415V/440V, 50/60Hz |

| Safety Devices | Thermo-over relay, Air pressure switch,

Full load buzzer, Timer, Control fuse,

Rotary valve sensor, Burner flame sensor,

Over-heat sensor |

*Use

high-quality kerosene or premium diesel only

| Item | PHS-130B |

| Heat Source | SUNCUE Biomass Furnace BB-18,

SUNCUE Rice Husk Furnace SB |

Capacity

Approx. kg | Paddy 1 liter=560g | 3,600~13,000 |

| Wheat 1 liter=680g | 4,370~15,780 |

Corn, Animal Feed

1 liter=690g | 4,440~16,000 |

Dimension

L(A)×W(B)×H(C) mm | Without CL-10 | 4,532×2,755×9,698 |

| With CL-10 | Horizontal Type | 7,617×2,755×9,698 |

| Vertical Type | Please contact the sales department |

Net Weight

Approx. kg | Without CL-10 | 2,950 |

| With CL-10 | Horizontal Type | 3,454 |

| Vertical Type | Please contact the sales department |

Required Thermal Energy

per unit | Paddy ‧ Wheat

Approx. Kcal/hr | 35,000~135,000

Ambient Temp. +10~40°C |

Corn ‧ Animal Feed

Approx. Kcal/hr | 220,000

Ambient Temp. +65°C |

Power Consumption

kW | Without CL-10 | 7.98 |

| With CL-10 | 11.78 |

Function

Paddy | Loading Approx. mins | 40 |

| Discharging Approx. mins | 35 |

| Drying Rate %/hr | 0.5~1.5 |

| Electricity | 3P, 220V/380V/415V/440V, 50/60Hz |

| Safety Devices | Thermo-over relay, Air pressure switch,

Full load buzzer, Timer,

Control fuse, Rotary valve sensor |

| Item | PHS-130G |

| Heat Source | LPG | NG |

| Max. Combustion Approx. | 16.6 kg/hr≒233kW | 18.2 m3/hr≒233kW |

| Type | Gun type |

Capacity

Approx. kg | Paddy 1 liter=560g | 3,600~13,000 |

| Wheat 1 liter=680g | 4,370~15,780 |

Corn, Animal Feed

1 liter=690g | 4,440~16,000 |

Dimension

L(A)×W(B)×H(C) mm | Without CL-10 | 4,308×2,755×9,698 |

| With CL-10 | Horizontal Type | 7,393×2,755×9,698 |

| Vertical Type | Please contact the sales department |

Net Weight

Approx. kg | Without CL-10 | 2,840 |

| With CL-10 | Horizontal Type | 3,344 |

| Vertical Type | Please contact the sales department |

Power Consumption

kW | Without CL-10 | 6.68 |

| With CL-10 | 10.48 |

Function

Paddy | Loading Approx. mins | 40 |

| Discharging Approx. mins | 35 |

| Drying Rate %/hr | 0.5~1.5 |

| Electricity | 3P, 220V/380V/415V/440V, 50/60Hz |

| Safety Devices | Thermo-over relay, Air pressure switch,

Full load buzzer, Timer, Control fuse,

Rotary valve sensor, Burner flame sensor,

Over-heat sensor |

Dimensions

Product Remark

◆Above numbers and drying rate are derived from reducing moisture in paddy from 26% to 15%, wheat/corn from 30% to 12.5% ─ for reference only. Actual results vary among different ambient temperature, relative humidity, grain varieties, hot air temperature, moisture content before and after drying.

◆Please apply low hot air temperature for drying paddy to prevent high breakage rate.

◆Gas pipe lines have to be built by certified local professionals. NEVER do it by yourself.

◆The required thermal energy is for reference only. Actual data will differ among grain variety, impurity rate, and drying condition.

◆Diesel/Rice Husk & Gas/Rice Husk Duel-type are made to order.

◆The specification and graph are for reference only. Actual specification of SUNCUE product shall be based on the Sales Confirmation which customers sign and delivered products.

◆The specifications of burner shown above are Japanese standard (Thermal energy: NG 11,000 Kcal/m³; LPG 12,000 Kcal/kg). Please consult with SUNCUE for burner with CE standard.

◆The density, composition and pressure of natural gas vary at different locations, thus thermal energy per m³ also varies. Ex: 8,900 Kcal/m³ in Taiwan, 11,000 Kcal/m³ in Japan, 8,400 Kcal/m³ in Sichuan province of China.

◆Different platform, rain hood, exhaust chamber, exhaust pipe, stand, balustrade and other accessories are required for each dryer and CL-10 model.

◆The user shall prepare dust collecting bags when using CL-10 without a central dust collecting system.

Related Products