- Product

Product Details

BB-18 Biomass

Furnace Drying Center

- Model:Biomass Furnace BB-18

About this product

Biomass Fuels

Constant temperature by Computerized auto control

High durability

Producing high price grain, improving competitiveness and profits

Product Introduction

SUNCUE BIOMASS FURNACE BB-18

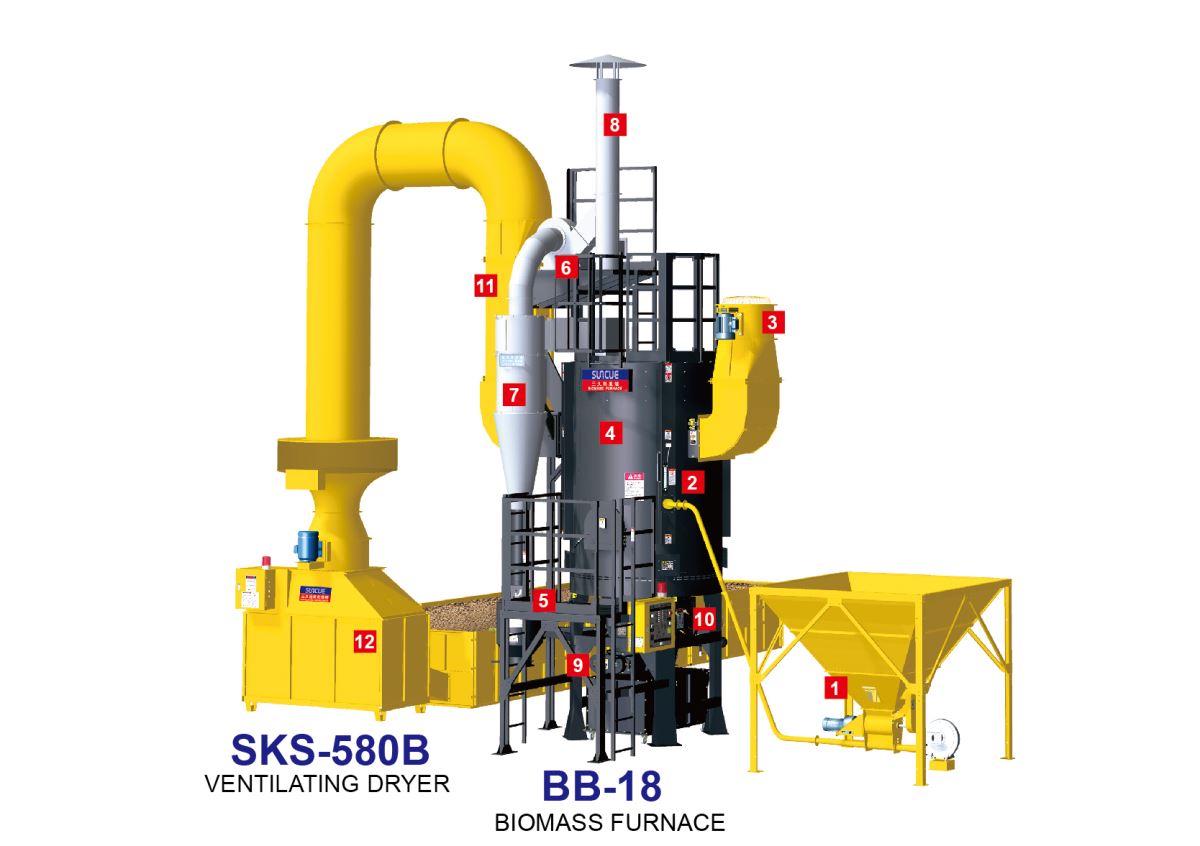

BB-18 with SKS-580B ventilating dryer

Husk feeder (Optional Husk feeding volume is set manually) Husk feeder (Optional Husk feeding volume is set manually) |  Furnace pressure meter Furnace pressure meter |

Blower Blower |  Biomass furnace BB-18 Biomass furnace BB-18 |

Safety maintenance platform (Auto ash discharge type) Safety maintenance platform (Auto ash discharge type) |  Exhausted blower Exhausted blower |

Cyclone Cyclone |  Chimney Chimney |

Automatic ash discharge system (Husk type) Automatic ash discharge system (Husk type) |  Auxiliary air blower Auxiliary air blower |

Hot air duct(Connecting pipe) Hot air duct(Connecting pipe) |  SKS-580B ventilating dryer SKS-580B ventilating dryer |

.No Diesel needed, energy saving, reducing CO2 emission, reducing drying cost dramatically.

.Various types of biomass fuels can be consumed. Low drying cost and free from high oil price.

.Biomass fuel:Paddy husk, Pressed straw bricks, Wood pellets, Corn cob, Coconut shell, Wood chip, Coffee hull

Paddy husk

Pressed straw bricks/Wood pellets

Corn cob

Coconut shell

Wood chip

Coffee hull

| Model | Manual ash discharge | Auto ash discharge |

| BB-18 | BB-18 AF | BB-18 ADF |

| Biomass fuel | Pressed straw bricks, Corn cob, Wood chip, Coconut shell | Coffee hull, Paddy husk | Paddy husk |

Max. thermal

energy Approx. Kcal/hr | 180,000

180,000=equals to the energy of 21 liters of diesel |

| Annual diesel saving Approx. | 60,000 liter/120 days 136,000 liter/270 days |

| Dimension L×W×H mm | 3,521 × 2,048 × 4,885 | 3,521 × 2,795 × 6,002 |

| Net weight Approx. kg | 3,420 | 4,150 |

| Dryer | SKS - 580B |

|

| Heating Way | Indirect hot air from

biomass fuel |

| Heat Source | SUNCUE Biomass

Furnace as an optional heat source |

| Dimension L×W×H mm | 9,038 × 2,458 × 3,016 |

| Drying Bin Single layer | 7.52m³, 17.52㎡ |

| Drying Bin Double layers | 18.19m³, 17.52㎡ |

Product Remark

.The specification and graph is for reference only. Actual specification of SUNCUE product shall be based on the Sales Confirmation which customers sign and delivered products.

.SUPER-300-240B, SUPER-300B is applied for drying paddy and wheat seed only.

.Max. thermal energy, husk consumption and exhausted ash production listed are for reference only. Actual data will differ upon variety, moisture content and impurity.

.Conditions of pressed straw bricks: ①Moisture content: less than 13%. ②Thermal energy: 3,700~4,200 Kcal/kg. ③Dust content: as low as possible.

.Above numbers and drying rate are derived from reducing moisture in paddy from 26% to 15% ─ for reference only. Actual results vary among different ambient temperature,

relative humidity, grain varieties, hot air temperature, moisture content before and after drying.