- Product

Product Details

SB-80 Rice Husk

Furnace Drying Center

About this product

Rice Husk Furnace Drying Complex

‧Easy operation-One operator can manage thousands of tons of grains per day.

‧Constant hot air temperature.

‧SUNCUE’s unique patented completed combustion technology.

Product Introduction

Rice Husk Furnace Drying Complex

SB-80 + PHS-320

Husk Feeder Husk Feeder |  Bucket Elevator Bucket Elevator |

Husk Tank Husk Tank |  Rice Husk Furnace SB-80 Rice Husk Furnace SB-80 |

Main Control Box Main Control Box |  Auxiliary Air Blower Auxiliary Air Blower |

Hot Air Duct Hot Air Duct |  Dumping Pit Dumping Pit |

Bucket Elevator Bucket Elevator |  Precleaner Precleaner |

Bucket Elevator Bucket Elevator |  Loading Chain Conveyor Loading Chain Conveyor |

32 ton husk type grain dryer 32 ton husk type grain dryer |  Micro Air Adjuster Micro Air Adjuster |

Hot Air Damper Hot Air Damper |  Unloading Chain Conveyor Unloading Chain Conveyor |

Easy operation-One operator can manage thousands of tons of grains per day

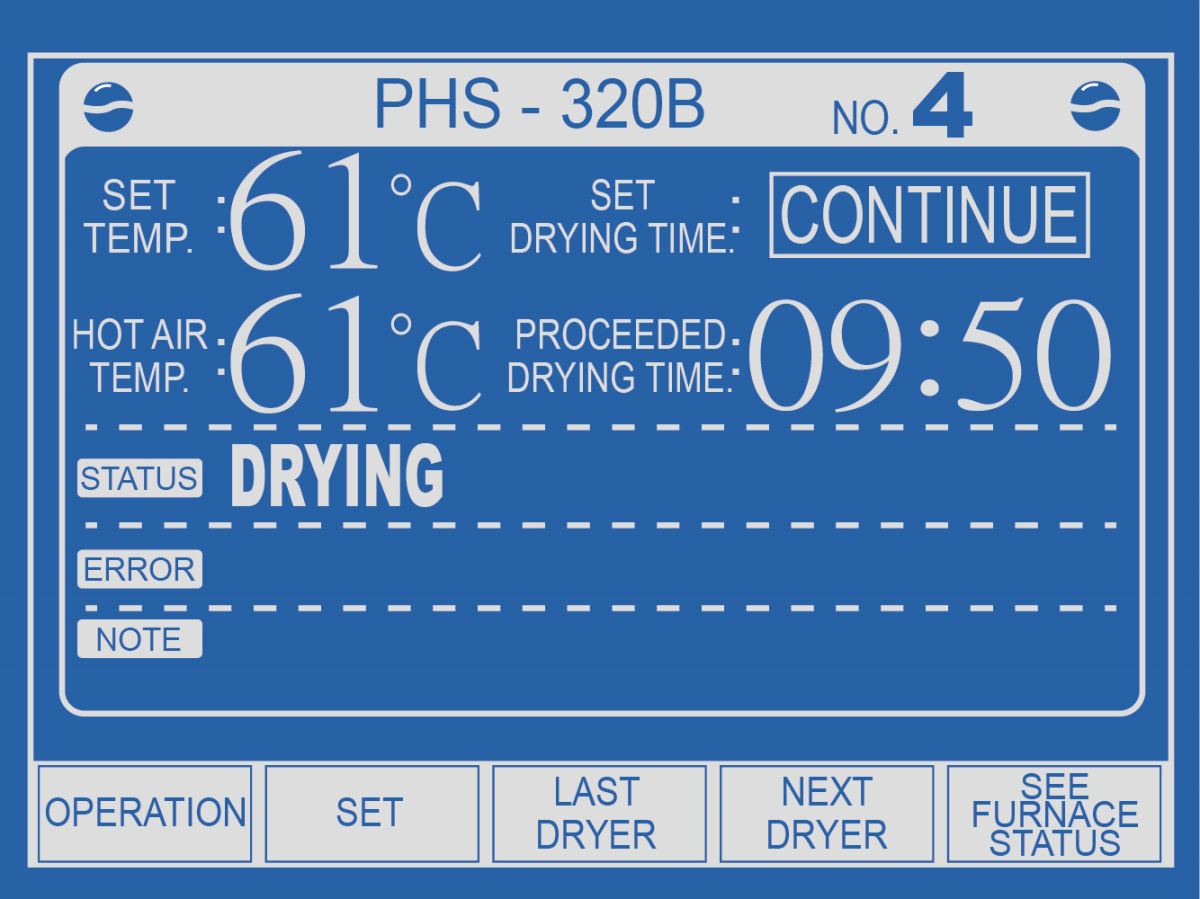

•Can connect multiple dryers. Allows different temperature settings on each dryer. Capable of maintaining constant temperature according to settings on each dryers.

•Simple interface, simultaneously control multiple dryers at constant temperature. Fool-proof design, the management requires no professional technician.

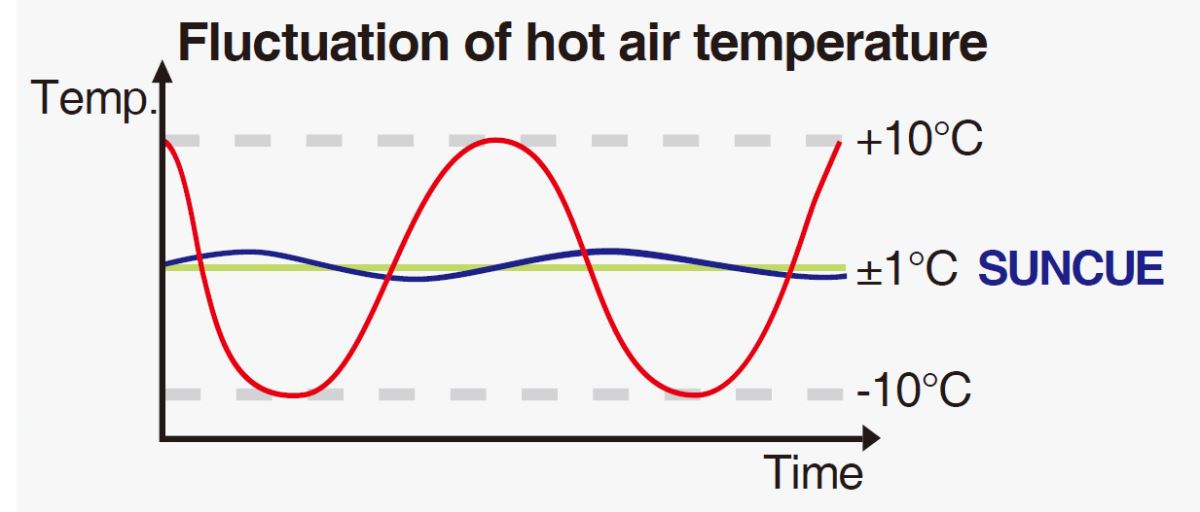

Constant hot air temperature

•Hot air temperature is controlled precisely within ±1°C.

•Hot air temperature is controlled precisely within ±1°C.

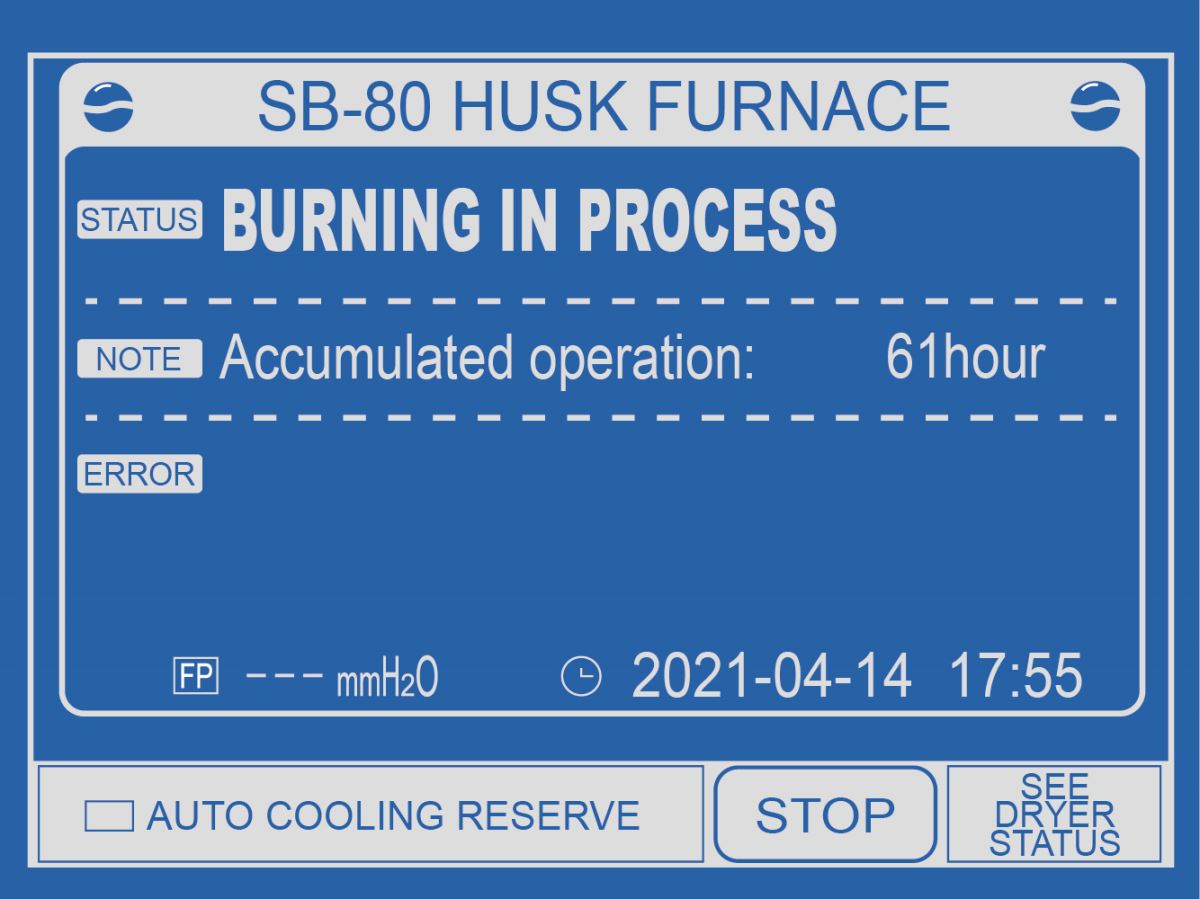

SUNCUE’s unique patented completed combustion technology

Consume the lowest quantity of paddy husk while produce maximum thermal energy. Paddy husk from 1 hectare of farm can dry approximately 3 hectares of wet paddy.

Paddy husk from 1 ton of wet paddy can dry approximately 3 tons of wet paddy.

The only choice for producing best quality small-package rice with the lowest cost

Low drying cost

Significantly reduces drying cost! You're no longer at the mercy of rising oil prices.

Easy management

Automatic computerized control, fool-proof design, easy operation.

Best rice quality

Drying at constant temperature produces the most high-quality rice, paddy seeds and wheat seeds.

High selling price

Indirect and clean hot-air at low temperature can produce the sanitary,

reliable of small package rice.Selling price will be high.| Biomass Furnace | SB - 80 |

| Max. thermal energy Approx. Kcal/hr | 800,000 |

Equivalent to diesel consumption. Approx. liter/day

Diesel thermal energy = approx. 8,400 Kcal/liter | 2,286 |

| Dimension L×W×H mm | 6,515 × 3,520 × 8,569 |

| Net weight Approx. in ton | 17.4 |

| Dryer | PHS - 320 |

| Heat Source | SUNCUE Biomass Furnace BB-18 , Rice Husk Furnace SB |

Capacity Approx. kg

(Paddy 1 liter=560g) | 7,800 ~ 32,000 |

| Dimension L × W × H mm | 6,671 × 4,871 × 13,410 |

| Net Weight Approx. kg | 6,600 |

Product Remark

‧Max. thermal energy, husk consumption and ash discharge production listed are for reference only. Actual data will differ upon variety, moisture content and impurity.

‧The specification and graph is for reference only. Actual specification of SUNCUE product shall be based on the Sales Confirmation which customers sign and delivered products.

‧The maximum heat output of each rice husk furnace is approximately 2.7 kg of CO2 emission per liter of diesel with a running time of 24 hours per day as calculation basis. Actual values may vary due to the users' various using factors.